In high-risk power environments, ensuring the physical separation of energized zones is a critical safety requirement. Fiberglass insulated fences (also known as FRP insulated fences) are increasingly becoming the preferred solution for power stations, substations, and utility maintenance sites—thanks to their outstanding electrical insulation and mechanical performance.

Below, we explore why FRP insulated fences are gaining popularity and what advantages they bring to modern industrial safety management.

Superior Electrical Insulation

Fiberglass Reinforced Plastic (FRP) is a non-conductive composite material with excellent insulation properties. When used in insulated fencing systems, it can effectively prevent current transmission and reduce the risk of accidental contact with live equipment.

This makes FRP fences particularly suitable for high-voltage workplaces, where isolating work zones is essential for personnel safety and regulatory compliance.

High Strength and Lightweight Design

One of the key advantages of fiberglass is its high strength-to-weight ratio. These fences offer excellent rigidity and structural stability under physical stress, including impact and vibration.

Despite their strength, fiberglass insulated fences are lightweight, making them easier to transport and install. This not only reduces labor intensity but also lowers logistics and deployment costs.

Corrosion Resistance in Harsh Environments

Unlike traditional metal barriers, fiberglass fences are inherently resistant to corrosion caused by acids, alkalis, salts, and moisture. They maintain their structural integrity and appearance over time—even in coastal, industrial, or humid environments.

This durability extends the product's service life and reduces the need for frequent replacements or maintenance.

Flame Retardant Safety Performance

FRP material is designed to meet flame-retardant requirements, offering additional protection in environments where electrical sparks, high temperatures, or flammable materials are present. The use of flame-resistant fencing helps contain fire spread and contributes to an overall safer worksite.

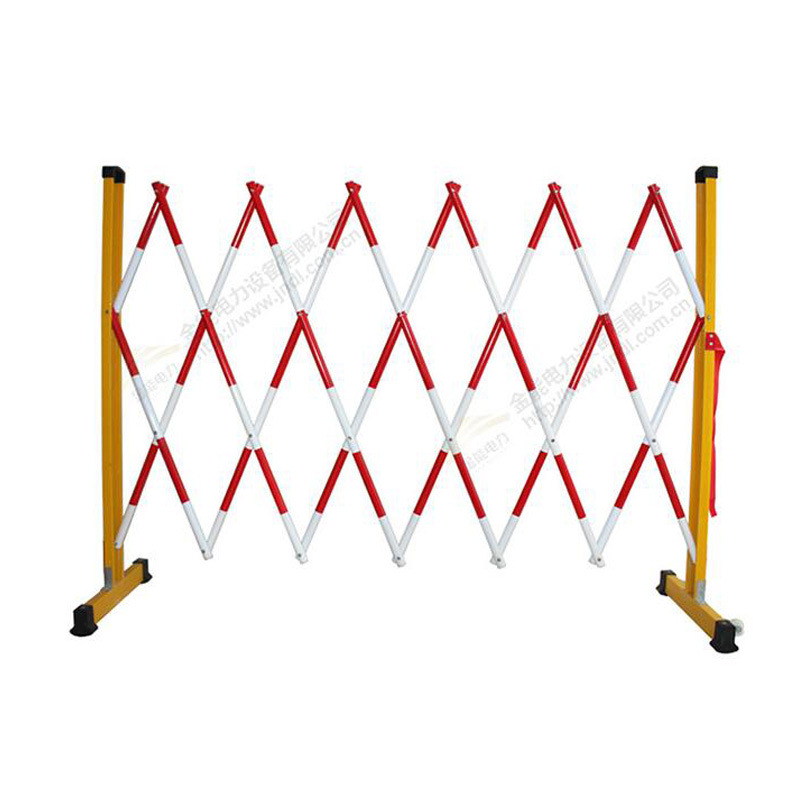

Customization and Telescopic Portability

FRP fences are highly adaptable to different working conditions. They can be easily customized in size, shape, or structure to suit specific workplace requirements. Many designs feature a telescopic mechanism, allowing the fence to be extended during use and compactly folded when not in service.

This functionality enhances mobility, saves storage space, and streamlines operational readiness.

Visually Distinct and Professionally Designed

Jinneng’s fiberglass insulated fences come in bright, eye-catching colors—typically red and white—which enhance visibility and serve as a visual warning. The smooth surface finish not only improves aesthetics but also helps in quickly identifying boundary lines on complex job sites.

Wide Industry Applications

Beyond the power industry, fiberglass insulated fences are also used in:

Telecommunications for isolating signal equipment

Transportation zones to restrict access during maintenance

Construction sites as mobile safety barriers

Factory and industrial plants for restricted zone demarcation

They can also serve as protective barriers to prevent small animals from entering sensitive electrical areas and causing outages or damage.

Conclusion: Elevating Electrical Safety with FRP Barriers

As safety requirements evolve and industries demand more reliable and maintenance-free safety solutions, fiberglass insulated fences stand out as a premium choice. Combining electrical insulation, structural strength, and portability, they represent a practical upgrade for companies prioritizing worker safety and operational efficiency.

Jinneng Electric Power continues to lead the way by delivering advanced FRP safety solutions, engineered for the most demanding work environments.