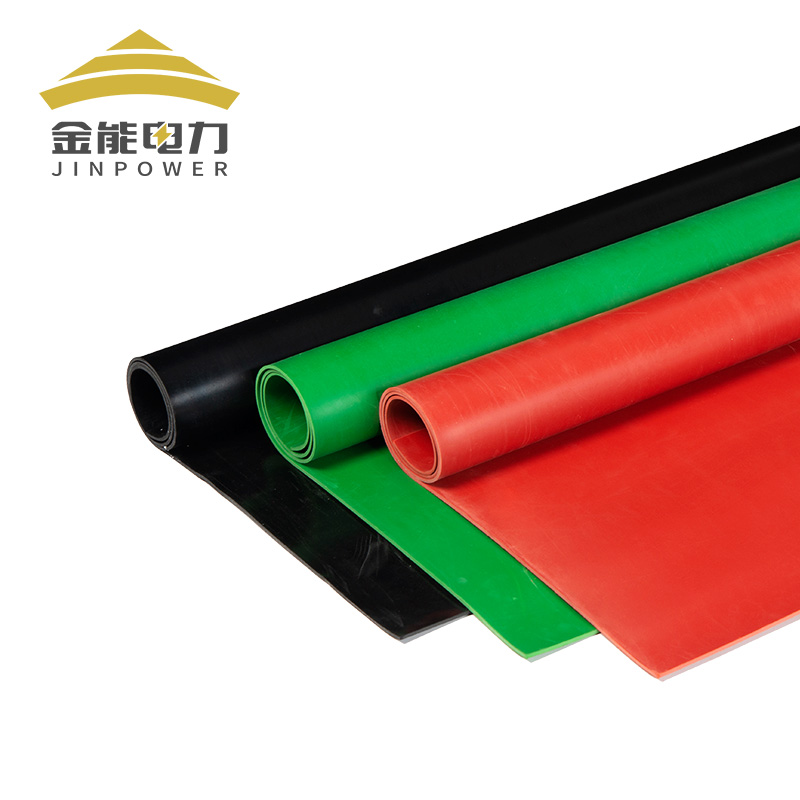

If you’ve been comparing switchboard insulating mats on the market, you may have noticed a clear trend: red rubber mats are consistently priced higher than black ones. This raises a natural question—why does the color red lead to a price increase?

If you’ve been comparing switchboard insulating mats on the market, you may have noticed a clear trend: red rubber mats are consistently priced higher than black ones. This raises a natural question—why does the color red lead to a price increase?

The truth lies not just in color, but in materials, production techniques, durability expectations, and quality control. In this article, we’ll explore the key reasons why red insulated rubber mats, such as those produced by Jinneng Power, come with a premium price tag—and why they may be worth it.

1. Higher Material Standards and Color Purity Requirements

Unlike black rubber mats, red mats require stricter material selection and refinement. In order to achieve a vibrant, uniform red that remains stable over time, manufacturers like Jinneng must:

Source higher-quality virgin rubber

Eliminate impurities that may interfere with color tone or gloss

Conduct multiple purification steps during the mixing process

This elevated raw material standard increases both material costs and processing complexity, but is essential for producing a durable, visually consistent mat.

2. Expensive Pigments and Additive Precision

Creating a true bright red rubber product is a technical challenge. To achieve this, the production formula must include:

Specialized red pigments that are both vivid and UV-resistant

Carefully measured flexibility-enhancing additives

Stabilizers that prevent fading, hardening, or chalking over time

These pigments and chemicals are more costly than standard black fillers. Moreover, tight control over dosage and dispersion is critical to maintain consistent quality, leading to additional R&D and testing costs.

3. Complex Manufacturing Process and Lower Yield Rate

The production process for red mats involves more labor-intensive mixing and monitoring steps compared to black mats. Color matching must be exact, and any inconsistencies in tone or gloss can render the mat unsuitable for sale.

Color blending and batch consistency are technically demanding

Red pigments require dedicated production runs to avoid contamination

Yield rates may drop due to more stringent visual and performance inspection standards

All of these factors raise both time and resource costs during manufacturing.

4. Higher Density and Transport Costs

Red insulating rubber mats often have a higher material density, making them slightly heavier than their black counterparts. This:

Improves physical stability and insulation performance

Slightly increases shipping and logistics costs per unit

Contributes incrementally to overall price differences

While not the largest factor, transport cost differences still play a minor role in pricing decisions.

5. Long-Term Color Durability and Aesthetic Value

Buyers of red switchboard mats often have higher expectations for visual quality and brand presentation—especially in:

Utility control rooms

Exhibition projects

High-visibility power installations

Jinneng’s red mats are designed to retain their original color and gloss even after long-term use, exposure to UV light, or heavy foot traffic. This aesthetic durability comes from decades of formulation experience and stringent quality management.

Conclusion: Premium Color, Premium Performance

While red insulating rubber mats are more expensive, that cost reflects greater attention to raw materials, process control, and finished quality. If you’re looking for a mat that delivers both safety and appearance—without fading, deforming, or releasing harmful substances—Jinneng’s red switchboard mat is a smart investment.

The extra cost is not just for the color. It’s for the commitment behind it.